Today we are proud to introduce you a brand-new kid microphone designed by Toyard. This is not only a children's microphone, but also a Bluetooth speaker. Let's take a look at how this kid's microphone is made.

The original intention of this kid's microphone (MIC-K17) designed byToyard is to allow children to express themselves confidently, to promote the parent-child relationship and to improve the quality of parent-child companionship. It takes 8 months for the kid microphone from design, molding, samples to mass production stage. The product shell is made of environmentally friendly lead-free ABS material, and the net head is made of non-toxic metal material, which fully meets the standards of domestic and foreign toy quality standard. At present, it has passed CE, Rohs, FCC, 3C and other certifications. In terms of product technology, imported oil injection technology is used to make the product look more comfortable and protect the kids’ hands in a better way! The microphone is rich in colors. The main colors right now available are pink, yellow and blue. If you look at the picture, there is also a cute little sticker on the speaker of the product, which makes the product look more heart-warming.

|  |  |

The children's microphone (MIC-K17) produced by Toyard is a combination of Five major components: The PCBA, speaker, microphone, metal mesh and rechargeable battery. We’d love to introduce you the specific details of these major components.

The PCBA is combined with the chipset that built-in reverberation and power protection, and built-in reverberation and sound-changing entertainment functions. There is an extra protection power chipset.

|  |

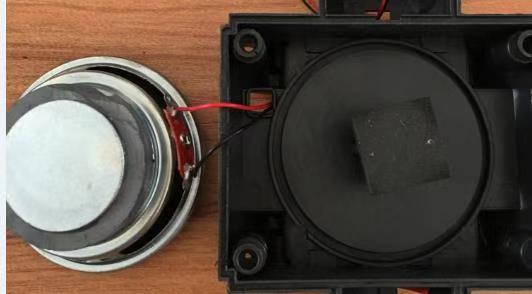

The speaker adopts 4 ohm 3W internal magnetic speaker, which is less interfered by external magnetic field, and the magnetic circuit is short. It enables the kid microphone work stably.

|  |

Metal mesh head, Toyard kid microphone metal mesh head process is sprayed with imported paint. We pay special attention to its safety as the metal mesh is close to the children's mouth. We must be sure it’s 100% safe!

|  |

What is more? Let’s take a look at details in the production process.The batteries for the product is used with UL certified brands, such as Changjiang brand.

During the assembling process, there are many parts and they are relatively small. Our workers are strictly trained to pass the company test before they can take up their jobs. Special attention is paid to the coordination of various positions in the assembly and product quality.

|  |  |

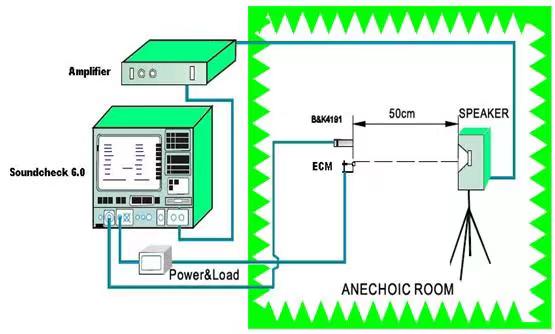

In terms of testing, it begins with the strict control of the incoming materials. It is necessary to ensure that all shell accessories are 100% in line with our company's standards before assembling. During the assembly process, we have many testing processes, semi-finished products are tested in a professional sound room; the whole machine is tested after the function and appearance are fully checked. Finally, after we complete the assembly of the kid microphone, we will conduct pre-delivery inspections. At present, our company has 12 QC personnel, and we check100% for bulk shipments.

|  |

What is more, our microphone package is a neutral English packaging designed by ourselves. We can also produce packaging according to the customer's design to complete the shipment.

In short, we strive to create the perfect microphone. We believe that only a good product can help customers win, and customers win means we can win as well! We will do our best to build the great kid microphone so to establish a win-win business relationship! Let’s bring a great future together!!